We are Steelworks

5 halls with 6000m² working area

Lise-Meitner-Straße in Borken in Münsterland is our home. We now work on over 6000m² of floor space and are constantly expanding.

Thanks to our different halls, we can strictly separate our areas from each other and thus always pay attention to the special features of the individual areas.

This enables us to offer the various processing steps under one roof and thus often shorten the production time.

Art projects in particular often require a lot of space for test set-ups and special tests.

We have sufficient space for this in our art gallery and can therefore take the individual requirements of the artwork into consideration.

65 steelworkers and 8 trainees

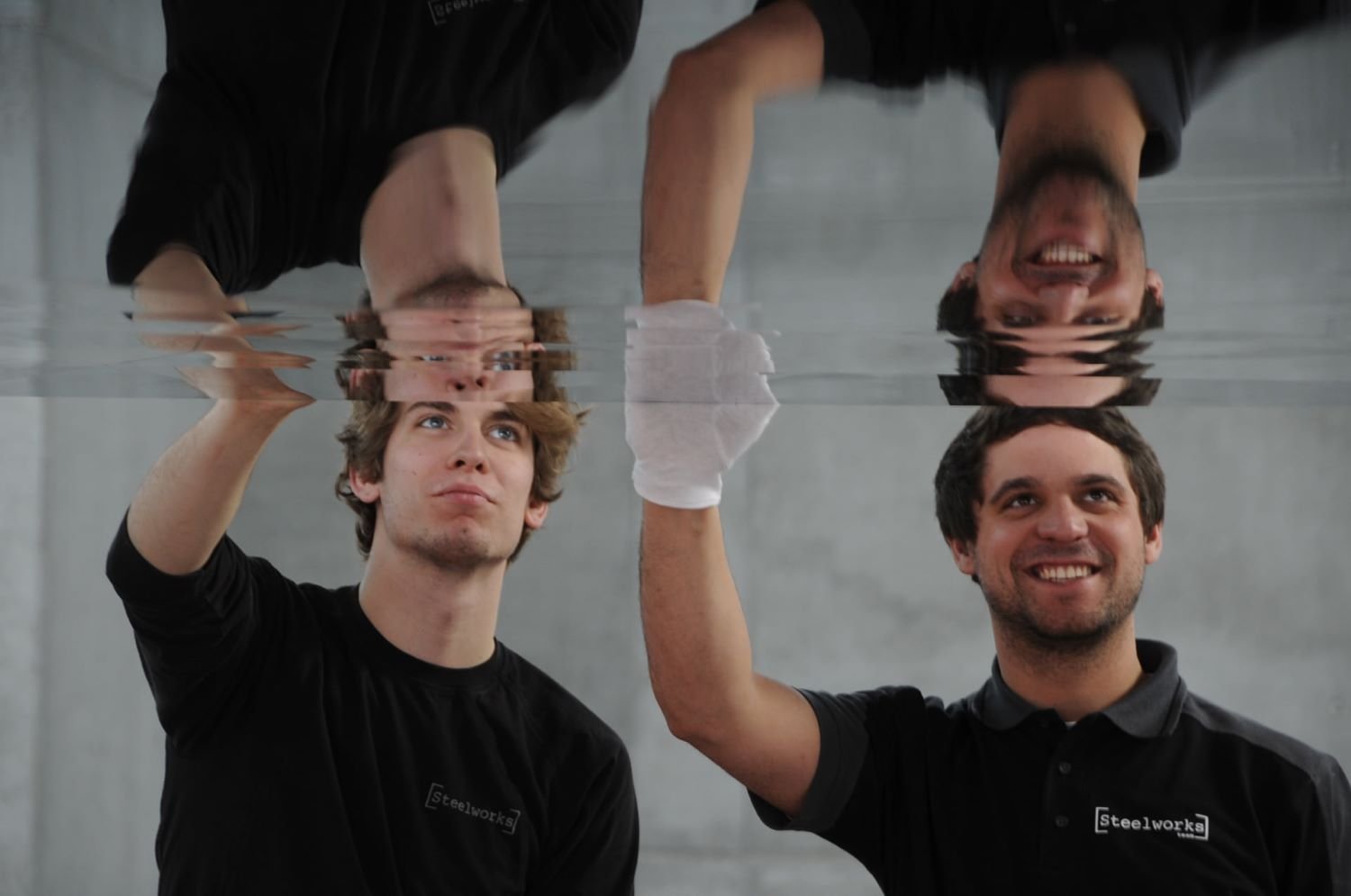

We are "The Steel People" - a team that is passionate and committed to working with stainless steel.

We are characterized in particular by our familiar working environment and the friendly relationship with our customers.

We never get bored: we often find innovative and creative solutions for the unusual projects we are allowed to work on.

Steelworks processes the material completely in-house in an unusual way

We design all your objects in 3D in close consultation with our 8 designers

We create 3D measurements with precise scanning systems on site for custom-fit designs

We visualize your objects in photorealistic quality

We mill stainless steel and a wide variety of metals, laminates, plastics and wood on 8 large-format milling machines

We grind and polish stainless steel surfaces to mirror-polished stainless steel surfaces on 4 large-format CNC grinding machines

We bend, roll, press and shape sheet metal and tubes into the most unusual objects

We hold patents on our exceptional processing of surfaces

We develop a wide variety of surfaces, colors, textures and coatings

We operate our own PVD system for coloring metals

30 YEARS OF EXPERIENCE

30 YEARS OF EXPERIENCE

1994

Thomas Reining manufactures his first stainless steel products as a sole proprietor with the company affix "Steelworks by TR"

1996

Merger with Uli Meerkötter, foundation of Reining & Meerkötter GbR in Rhedebrügge; Marc Meerkötter already supports the production as a student

1998

Relocation to Heinrich-Hertz-Straße in Borken and recruitment of the first employees

2002

Training of the 1st apprentice Dennis Fellerhoff (our current workshop foreman)

2003

First Airbus A-380 handrails for Emirates and Lufthansa are built in Borken

2005

Uli's son Marc joins Steelworks as a master metalworker

2007

Change of name to Steelworks GmbH & Co. KG

2008

New building and move into the main hall at Lise-Meitner-Straße 20 in Borken

2008

VW Autostadt Premium Club House

2009

Entry into the yachting scene with first yacht building interior projects after the economic crisis

2011

Entry into the international art scene

2014

Marc Meerkötter becomes a limited partner and officially joins the management team

2020

Creation of major art projects during the Covid-19 period "The Hive" and "Eye of the North"

2023

Uli Meerkötter resigns as limited partner

An article that appeared in the Borkener Zeitung in 2017 as part of the series. "KÖPFE: Founders, owners and decision-makers in the region".

-

"A small workshop in rural Rhedebrügge - this is where construction mechanic Thomas Reining started out in 1996 with lots of ideas in his head. His goal: to turn them into creative steel objects and try out new techniques in the process. "Doing things differently" was the basis for the successful development of the company and is still the driving force behind every Steelworker today.

The creative mechanic inspired his friend, metalworker Ulrich Meerkötter, with his ideas and together they forged plans and objects. They constructed and designed high-quality stainless steel objects - everything a house needs. Soon the time was ripe for a larger location.

Gradually, commercial customers also became aware of the creative workshop's unusual ideas. As a result, the focus shifted to the design and production of exclusive work for national and international customers for shopfitting and trade fair construction - from decorative trim to complex components, whether for Dior boutiques or the Toyota trade fair stand.

Ideas were flowing, business was booming, deadlines were pressing and the team was growing. "We didn't have to worry about new customers," says Managing Director Ulrich Meerkötter. During this time, the second generation also became infected with a passion for steel.

Marc Meerkötter was already shaping things out of scrap metal at a young age. He found his dream job when he trained as a master metalworker and joined the company.

The economic crisis caused a cutback. Orders in the shopfitting and trade fair construction sector declined, but the steelworkers used this as an opportunity. The creative minds finally found time to devote themselves to their original passion again: inventing innovative techniques for stainless steel processing and experimenting with shapes and surfaces to achieve unique visual effects.

"The results always lead to new techniques," explains Marc Meerkötter. Experimenting and finding perfection in the details - that is the challenge that drives the steelworkers. They design, plan and produce projects in 3D and realize the most spectacular ideas and revolutionary shapes.

In 2008, Steelworks moved into its new building - a hall that resembles an artist's studio on the inside. Around 65 employees work here today. One team uses specially developed, patented technology to manufacture stainless steel accessories for yachts such as the world's largest sailing ship, the "White Pearl", while others work on projects such as the exclusive mirror installations in the Premium Clubhouse at the Autostadt in Wolfsburg, and still others on staircase handrails for Airbus, logos and lettering or installations for internationally exhibiting artists.

Marc Meerkötter has also been part of the management team for two years. A harmonious triumvirate: Thomas Reining is the creative one, Ulrich Meerkötter the steady one, his son Marc the technician.

Together with their team, they live the passion for steel."

Stainless steel design objects

When passion creates something new: We were so inspired by our projects that our Mirroc® brand was born.

Mirroc® brings our design objects made of mirror-polished stainless steel into the living rooms of design lovers all over the world.

Because we want to make the perfection and uniqueness of our craft tangible and accessible to as many people as possible.

Our values

TEAMWORK

We live and breathe teamwork! Not only through our family working environment internally, but also through the close cooperation with our customers. We know that: Together we achieve the best results.

PRECISION AND ACCURACY

Absolute precision and exact processing: We are precise when it comes to the assembly of stainless steel parts and material quality. This makes us one of the strongest partners for mirror-polished surfaces worldwide.

TOP QUALITY SOLUTIONS

We implement your ideas and wishes - and often create innovations as a result. 30 years of experience have shown us: We find solutions. And in the best possible quality.